Cut OBW/Hexified Panel Quilt Panels from the Same Bolt

To make a Hexified Panel Quilt you need seven (7) panels or for a basic One Block Wonder six (6) repeats for hexies or eight (8) for octagons. Having faced this issue myself with a student in a classes and also a project of my own, I've learned it is critical, if at all possible, to have all of the panels that will be cut into strips and triangle sets be from the same bolt. For Hexified Panel Quilts, having the seventh uncut panel to frame come from a different bolt is probably acceptable, but preferably not the six panels to be cut. Some differences may be subtle like variances in color saturation, while others are much more obvious with actual differences in panel or block sizes.

When fabric is produced, each run may come out slightly different. The ink saturation may vary making one run darker or more vibrant than the other. As finished fabric is run through the machine to fold and roll the fabric onto bolts, it may stretch or tweak differently by bolt. If a fabric is popular, a new printing may be done that starts with different greige goods (raw fabric before dyeing or printing) or even a different manufacturing plant. Each of these factors can make the panels or blocks vary from bolt to bolt. These issues can definitely cause problems when trying to line up your layers accurately to cut strips and sub-sets.

I first came across this problem in 2016 when a quilter in one of my classes

had purchased panels over the internet. She got three from one vendor

and four from another to make up her seven panels for a Hexified Panel

Quilt. What we discovered together was that the panels from the two vendors

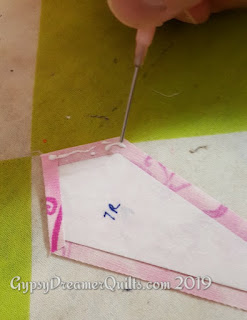

were printed differently. The width of fabric on one set was over 1" longer than the other, throwing off the alignment of the two sets of panels. The 24" panel width along the straight of grain was

pretty close on both sets. We decided together to have her cut the strips across the straight of grain panel width and readjust her pins aligning layers

after each cut to keep the WOF print close to the same. It was a tedious

process with a fair amount of waste, but together we got all of her strips and triangle sets cut and

she did eventually complete the project.

After seeing these gorgeous Elizabeth's Studio Hummingbirds & Flowers block panels at the 2019 Spring Quilt Market in Kansas City, I ordered two bolts to cut into kits for my classes and workshops. A few weeks after Market, I received a call from the warehouse manager saying they had several partial bolts and asked if that would be okay. Not giving it a lot of thought and not remembering my experience in the 2016 class, I said I'd take them all. I soon received three bolts--one 7 yard bolt with ~10 repeats, one 11 yard bolt with ~16 repeats, and one full 15 yard bolt with ~22 repeats. I hoped there would be enough repeats to make multiple kits for future workshops.

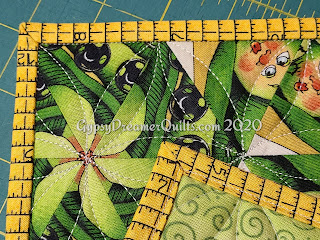

I pulled the two partial bolts down from the stash closet and began cutting the panels apart into four kits each--two blocks half width of fabric by one block wide. For the sample I was going to use the odd number of blocks from each bolt, making sure I didn't give anyone else the possibly difficult blocks to match up. I soon discovered that while they appeared the same, they were printed very differently. After cutting the blocks apart and starting to line up one set of six with pins, I noticed they weren't matching up at all. As a test, I folded one set of blocks in half and laid it over the

same set of blocks from the other bolt and you can see the clear

difference.

The light blue border surrounding the blocks was a different width between the blocks. Even the blocks were not the same size. Looking closer, the selvedge on one bolt had the light blue background going right to the edge of the fabric, whereas the other bolt had a white selvedge with the blue starting half inch from the edge. Still, the information printed on the selvedges was the same. I separated the blocks back into separate piles by bolt and had to rethink my plan. I then took down the third bolt to check it against the other two.

Even on the two bolts that were printed the same, the color saturation was definitely darker on one bolt than the other as you can see between the blocks on the left and those on the right. Mixing those two sets to make hexies would make interesting hexies with uneven color saturation.

There are so many ways to adapt and tweak the One Block Wonder technique and its variations. I've used repeats across the width of fabric in order to get six repeats when I only had yardage enough for three or four of the six. I've seen others use mirror image blocks, lining up right and wrong sides of fabric to match up the print, to create very unique hexies when all six layers are then laid out with all right sides up. Regardless, in my opinion, if you have two bolts that are so different as the two I received, there may be no way to accommodate this much variance. With a full size panel it can possibly be done with care as my student and I learned back in 2016; however, with the smaller blocks especially, the variance between the two bolts I received was too great to bridge.

More snippets from the sewing room soon,

Liz